Air Replaces Water at Saqqara

| |

| Members of a Diggings tour examine the lowest chamber in the Great Pyramid. The way in which the rock has been carved is clearly visible. |

So far as we know, Khufu's workmen tunnelled into the bedrock in order to create the lowermost chamber of the Great Pyramid. In fact, in the area beyond that chamber, where there is an unexplained extra 30 feet of tunnel, it is quite clear that the rock has been cut through to make the low, narrow passage. Clearly Egyptian stonecraft had come a long way since the first pyramid was built at Saqqara.

There, the first action of Imhotep and his team was to dig a vertical shaft, 23' square and 92' deep, at the bottom of which they built the tomb chamber using blocks of pink granite from Aswan. The chamber was 9'9" long and 5'6" wide and high. Entrance to this burial chamber was via a hole bored into one of the granite slabs that formed its roof and after Djoser's mummy had been placed in position, the hole was fitted with a 6' granite plug that weighed three tons and must have been a nightmare to move in the confined space underneath the pyramid.

| |

| The burial shaft at Abu Roash, where the unfinished pyramid has been stripped away by stone robbers to reveal the shaft, similar to that at the Step Pyramid. |

This was all very well, but that left a huge hole, 23' on each side, which had to be bridged so that the pyramid could be built over it. The Romans, of course, would have made short work of the problem by building an arched vault, but the ancient Egyptians were not aware of the strength of the arch - may not even have invented it yet, though arches were in use by the Twelfth Dynasty. Instead they resorted to a sort of corbelling, laying courses of stones, each one projecting a little further over the void until they met in the middle. A fragment of this corbelling can be seen in the ruins of the Abu Roash pyramid, which used the same method of a deep shaft for the burial chamber.

Corbelling is fine - I've just come back from a trip around Ireland where beehive huts with corbelled roofs have survived everything the weather can throw at them for two or three thousand years - but it assumes that the roof isn't going to be terribly heavy. Unfortunately, that is not a safe assumption with a pyramid. The Irish had nothing more than the sky above their corbelled roofs, but Djoser had several thousand tons of stone resting on the roof over his granite burial chamber!

| |

| I climbed down to the bottom of the shaft and then took this photograph looking up at the remaining fragments of the roof of the burial shaft. |

Like the camel's back, rock has a breaking point, which is why the builders of the pyramid had to resort to corbelling rather than simply cutting slabs of rock 25' long and placing them over the tomb shaft. On the basis that a short stick is harder to break than a long one of the same diamter, the workmen appeared to have tried to avoid breakage by using relatively small stones in the corbelling, not realising that the breaking strength remained the same and the sheer weight of stone above overwhelmed all their calculations.

They were saved by something they probably didn't even have a name for - friction. Under the enormous weight of the pyramid, the corbelled roof sagged inwards and the blocks of stone jammed against each other, forming an immoveable mass that appeared to be just as good as the most finely engineered roof. No one could move those stones, they appeared welded together into a solid mass - it would have taken an earthquake to shift them.

And that, alas, is precisely what it did take!

| |

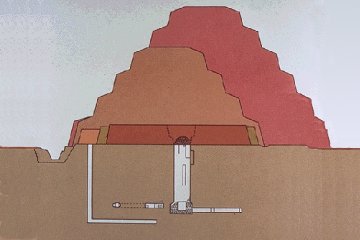

| Diagram of the Step Pyramid, showing the stages of its construction and a hint of the network of underground passages beneath it. |

Back in 1992 Egypt was hit by an earthquake with a magnitude of 5.8 on the Richter Scale. The epicentre was just south of Dashur, with its Bent Pyramid, but the effects were felt over much of northern Egypt. In Cairo 350 buildings were completely destroyed and a further 9,000 badly damaged, leaving 50,000 people homeless. 545 people were killed, mainly in the panic that followed the earthquake, and a large block of stone tumbled down from the Great Pyramid of Gizeh. Almost half the historical monuments in the Cairo area were damaged.

Among them was the Step Pyramid of Djoser. Previous earthquakes - the last major one was in 1847 - had left the passageways and tomb chamber of the pyramid sufficiently unsafe that it has never been open to tourists and archaeologists who entered it held their breaths and walked delicately like Agag until they emerged into the open air again. Investigators who entered the pyramid after the 1992 quake emerged looking pale and shaken and for the last 19 years no one has been inside the pyramid and serious fears were entertained for its safety. An underground collapse might simply result in a small depression in the top of the pyramid, but it might also trigger a general collapse and reduce the pyramid to a mere mound of rubble, rather like that which surrounds the Meidum Pyramid!

| |

| Cintec is proud of being Welsh and makes sure that "Made in Wales" is emblazoned on its products. |

Things move slowly in the east and with more important things - like posing for cameras and harrassing Western archaeologists - occupying his mind, the former head of Egyptian Archaeology, Zahi Hawass, had little time to spare for the mere preservation of a pyramid. However some sixteen years after the pyramid was damaged, he finally got round to doing something about it. British engineers Cintec, who worked on the restoration of Windsor Castle after the disastrous fire in 1992, was awarded the contract and came up with a clever idea.

Part of the problem was that the mass of rocks that made up the roof of the chamber was completely rough and uneven. If you had used steel props, pushing one stone up would merely loosen three or four others and result in the dreaded general collapse. If you used a forest of steel props or jacks, not only would there be no room for the workmen in between the hundreds of props, but how could you guarantee that each jack was applying the same pressure to the roof?

Fortunately Cintec had the answer. Peter James, the head of the company, was a former officer in the Royal Navy and had developed a system called "Waterwall" for protecting people and buildings against the effect of explosives. Basically this was one or more strong plastic bags filled with water which you placed around the bomb - or around the building you wanted to protect. When the bomb went off, although the plastic bags might be punctured, the mass of water cushioned the blast and protected whatever was behind them.

James concluded that his water-filled bags would be the ideal answer to the problem. As they filled with water, they would mould themselves to whatever they were pressing against and would apply equal pressure to every single stone and particle of sand they encountered. Perhaps equally important, they would be easy to manoeuvre and position within the confined space of the pyramid.

| |

| Cintec's giant air bags support the unstable roof of the burial chamber while stainless steel reinforcing rods are inserted. |

Once the roof of the burial chamber had been supported and stabilised, the plan was to insert stainless steel rods as reinforcement anchors to pin the roof together so that it would remain in place once the water-filled bags were removed.

That, at least, was the theory. Earlier this year James and his team finally got down into the underground passageways of the pyramid and, hard hats jammed firmly on their heads, were able to examine it. To their horror they discovered that the lumps of limestone that made up the roof were full of sharp edges and jagged points which were almost certain to puncture one or more of the Waterwall bags, releasing thousands of gallons of water into the tomb chamber.

To explain why this would be a disaster we need to make a short excursion to the Valley of the Kings. The rock there consists of a thick band of good-quality limestone, beneath which is a layer of powdery shale. Those who have encountered it describe it as having all the strength and consistency of wet corrugated cardboard. (If you don't know what that is like, I'm sure you can find an un-needed box or two at your local supermarket with which you can experiment.) It also has all the characteristics of a sponge.

Most of the tombs in the Valley of the Kings are cut into the limestone, but one or two break through this layer and encounter the shale. The builders, apalled by their mistake, hastily covered the floor with a thick layer of limestone plaster and the pharaoh concerned probably never knew the difference. The plaster, however, was not waterproof.

| |

| Another advantage of the collapsible air/water bags is that they can be inserted in small spaces, such as the gap between the burial chamber and the roof of the pit. I am grateful to Cintec for supplying these three pictures. |

From time to time there is rain at Luxor, sometimes in sufficient quantities to send cascades of water roaring down from the cliffs around the Valley and into the Valley itself. So long as the tomb shafts were protected by their doors or, in later years, by the thick layer of sand and rubble that accumulated in the entrance, everything was fine, but once archaeologists got to work and cleared the passageways, the first flood brought disaster.

It was bad enough that the water flowed down the painted corridors, damaging the priceless frescoes and flooding the tomb chamber. The real disaster came in those tombs which had penetrated to the shale level, for the shale absorbed the water thirstily and as the bone-dry shale sucked up the water, it swelled and expanded.

Water is a remarkable force. The expanding shale thrust in all directions, actually lifting the limestone layer above it. The area with least resistance, however, was the tomb chamber itself, where there was only empty space, and the shale swelled up into the chamber. In some of those chambers, baulks of rock had been left as pillars to support the roof and as the shale heaved upwards, the pillars were compressed against the bulk of the mountain above them - and something had to give.

Naturally, it was the pillars and, to a lesser extent, the walls of the chamber. The pillars cracked and broke, sometimes almost explosively and sometimes bringing down the roof of the chamber.

The rock beneath the Step Pyramid is bone dry and has been for thousands of years. We do not know what lies beneath the tomb chamber, but Cintec - wisely - were unwilling to try the experiment and see if the rock would swell and bring the pyramid tumbling down around their ears. Instead of water, therefore, they are using compressed air. If an airbag is punctured, they can either deflate it and apply a patch or they can simply turn the compressor up a notch and rely on being able to pump the air in faster than it escapes. In either case, the pyramid itself will not be endangered.

slabs of rock 25' long That, of course, is to assume that Imhotep's workmen had the technical ability to quarry and move such massive blocks of stone. In fact, it is notable that in this first monumental stone building the builders used stones little larger than the mudbricks of their day. It appears not to have occurred to them that the work of cutting and shaping the stones could have been vastly reduced by making them bigger!

If you can imagine four bricks piled side by side with another four placed on top to make one large block, although the sides of the block are twice as large in each direction as the individual bricks, the internal faces of the bricks are part of the block. Out of the six faces of each brick, only two need to be finished, reducing the labour by two thirds! Return

breaking strength We need to distinguish between the ease with which a stick can be broken and the actual strength of the wood. A long stick is easier to break because you can hold it with your hands further apart and apply greater leverage. If you put your hands close together, then the long stick is no easier to break than a short stick! All that happens with the long stick is that the lever effect has multiplied the force you exert with your hands.

Let us suppose that a piece of wood - or rock - one foot long breaks under a load of 100 lbs concentrated at its end. If we now make the piece two feet long, it will break when 50 lbs are piled on the end. Conversely, make the piece 6" long and it will break when 200 lbs are placed on the end. The strength of the wood or rock remains the same; all that has altered is the leverage applied to it.

The Egyptians were master builders, but they appear to have lacked a theoretical basis for their achievements and proceeded on "rule of thumb" calculations. Their fallacy appears to have been to think that a short stone was stronger than a long one. Return

British engineers Cintec This is not the first time Cintec has rescued a pyramid. A few years ago they pinned some of the huge blocks of stone which spanned the corridors in the Red Pyramid at Dashur, which had cracked because of the huge weight of stone above them. Further details can be found on their website. Return

it swelled I hope I am not being too dramatic with this choice of words. The effect probably only amounts to a fraction of an inch, but when that force is being applied to incompressible rock held down by a mountain of the same stuff, even a fraction of an inch is pretty impressive. Return

© Kendall K. Down 2011